|

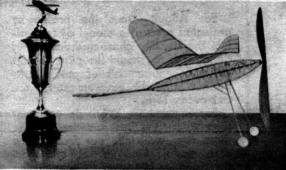

The 23rd Air Trails presentation of a championship model In collaboration with Lawrence N. Smithline Bloomingdale Trophy Winner

ALL that remained of a once-proud Class C tractor was the microfilm-covered wing. The rubber had just collapsed the motor stick and the delicate, microfilm-covered tail group was demolished. As Alvie Dague, Jr., walked across the floor of the Olympia Stadium that 1936 summer afternoon in Detroit, his spirits were at their lowest. For months he had carefully adjusted that indoor tractor for the Stout Competition at the National Contest, and now just as he was winding for an official flight his model blew up in his face. True, he reasoned, he had an indoor fuselage model, but what could one expect from a model that had a wing heavy enough to support an outdoor job? At one time that ship had been adjusted, but it had not been out of the box for months. He opened the box anyway and the model looked fine. If only those wing spars were lighter! And almost by accident he remembered that the tractor wing of the plane that had just been demolished was exactly the same as the fuselage wing. The stick wing, although it was quite light, seemed amply strong enough to do the job, and he immediately started to transfer the wing mounts from the heavy to the light wing. He assembled the model while hoping that the adjustment had not changed. At four o'clock in the afternoon (which it then was) he hand-wound the model, and much to his amazement, it did five minutes. In order not to waste a valuable minute by further test flights he wound the model 1,500 turns for an "official," in which, in spite of a stalling flight, it remained aloft for over 12 minutes. Literally shocked by such excellent results, he paused long enough to take the stall out of the flight and then put in 1600 turns just to see if there were any more surprises in store. There were! By the time the watches said 9 minutes the model was near the ceiling dodging lights, rafters and other planes. On the way down it got caught with another ship and started to spin down, but they got free and went on flying. When it touched the floor the time was 16 minutes, 17 seconds -- and the Bloomingdale Trophy was won. At the 1937 Nationals, which were held in the Grosse Isle blimp hangar, Alvie Dague was well prepared -- he had his old fuselage model and two new ones. On the first trial, the rubber broke and ruined the fuselage on one of the latter. After working all day with his tractor and the other new model without much success with either, he again turned to his old fuselage model. It was about four p. m. again when he assembled the 1936 winning ship. It turned in a very satisfactory test flight and only minor adjustments were necessary to get it into top form. On the first flight he put in 1650 turns and let it go. Valuable turns were lost as it hit another ship about four feet above the ground, so that the take-off had to be done over. The climb of the ship was very good but not nearly as peppy as the year before. It got to about 85 or 90 feet and, after a very slow descent, it landed after 15 minutes, 41 seconds. His next "official" he decided would be a record trial; however, his luck had abandoned him. While winding the rubber, which should have been capable of holding 2000 turns, it broke, badly damaging the fuselage. He felt quite sure his one flight was not long enough to win the much-desired Bloomingdale, but much to his surprise the flight was the best in both senior and junior divisions. This model, Dague feels, is easily capable of breaking the 17-minute record for Class C ships. FUSELAGE Make full-sized drawings of the fuselage sides. Pin the longerons in place and cement in the cross-braces. After the sides are completed put in the upper cross-braces and then brace the fuselage with 3/32" superfine strips as shown in the drawing. Cover the fuselage and cement on the landing gear. Note that the landing gear struts are braced with 1/32" round struts. The wheels are made of 1/64 " sheet balsa and have a 1/16" round hub cemented in the center. WING A full-sized drawing of the wing should be made and the spars, which are sanded to an oval cross-section, should be pinned to it. When laying the spars down be sure to pin them in line with the rib shape. The tips can be bent around a cardboard template and then cemented in place. Cover the wing in one piece (with microfilm, of course) and then put in the dihedral. The wing mounts are cemented permanently to the wing and are not clipped to the fuselage mounts but merely temporarily attached with a dot of cement so that they can be easily removed. BOOM TAIL AND RUDDER The boom is bent from a blank 1/64' thick around a former to a tear-drop shape. It should be cemented to the rear plug (seam of boom on the bottom) which is made by crossgraining two 1/32" sheets of balsa, one of which fits snugly inside the rear bulkhead and the other of which fits outside. Before cementing the boom to the plug cement in place the rear hook, which is bent of .018 wire. Make the tail and rudder to the dimensions shown and insert the ribs. Note that the rudder has a flat section, and the tail a cambered section. Cover the surfaces and cement them to the boom. Both tail and rudder have 0° incidence. PROPELLER The propeller is made from a block of 1 x 1-1/2 x 17 cut as shown in the drawing in order to quartergrain the blades. Cement the two halves together and carve the block in the usual manner, concave side first and then the convex side. Make a template of the blade shape and cut the blades to fit. A wire shaft should be cemented in place. Note that a special shaft is used so that the propeller may be held with a plier when winding. ASSEMBLY AND FLYING Cement the wing sticks on the fuselage wing mounts. Insert a 21-1/2" loop of 1/8" brown rubber and attach it to the rear hook and propeller shaft. Check the setting of the wing by first flying the ship with some handwinds. If the model stalls you will have to move the wing back, if it dives, forward. The model should turn in about forty-foot circles. Alvie Dague believed his model, which was his first serious attempt at building an indoor fuselage model, could do 17 minutes. Let's see if you can do it. WEIGHTS

Scanned From June 1938 |