|

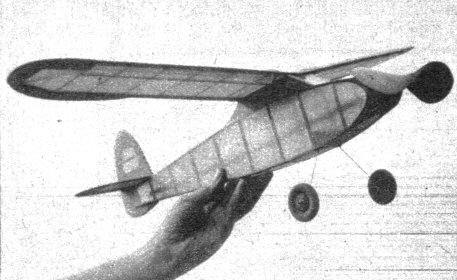

QUICKIE Simple construction and a minimum

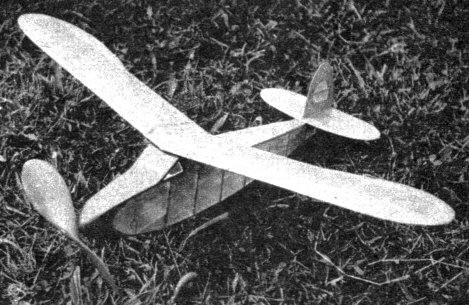

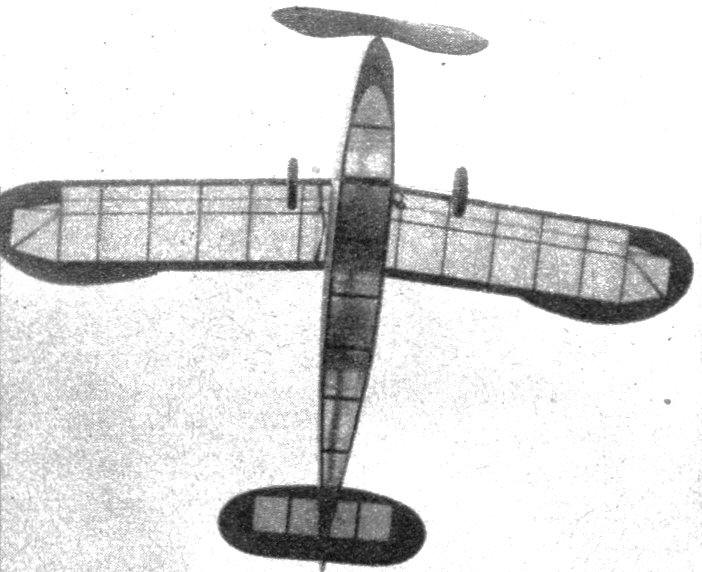

THE QUICKIE is designed for swift construction and snappy performance. Although we do not recommend trying to build it at a single sitting, two evenings should be sufficient to get it into the air. Structural pieces are held to a minimum; curved sections of wing and tail are cut from sheet balsa in the easiest manner possible. Minutes have been sacrificed here and there to provide a few frills to make the job more attractive. CONSTRUCTION Fuselage. The side view is symmetrical, both 1/8" square longerons following the same bend. The nose cross pieces are wider to take knocks. The top and bottom cross pieces are shown in a group. No top view is necessary. Lay wax paper over the drawings and pin the longerons in place directly on the plans. Cross pieces are cut to size and cemented in place. When dry, remove the side frames from the form and assemble them to each other at Stations 3, 4, and 5. Wrap a rubber band around the nose to pull it into position while its remaining cross pieces are glued in position. Pull the rear of the longerons together, install the rudder post complete with rubber hook, and the remaining top and bottom cross pieces. Cut two cabin sides from 1/8" soft balsa sheet and glue one atop each upper longeron in the proper position. A 1/16" sheet bulkhead holds these cabin sides in alignment and supports the 1/16" sheet V-shaped cabin roof. Details of the landing gear are given on the plan. Finish the landing gear and install it before covering the fuselage. Use hardwood wheels. Tail. The stabilizer is made from four pieces of 1/8" soft sheet as shown by the plan. The rudder requires three pieces. Notches are cut for the cross pieces and the tail is constructed by pinning the various parts directly over the plans until the cement has dried. Round the leading edges and taper the trailing edges. Wings. Thirteen ribs are cut to the pattern given from 1/16" sheet balsa. Pin one of the 1/16 x 1/4" spars over the plans as the rear spar and cement the ribs on it in the proper locations. Preshape the 1/8 x 3/8" trailing edge and pin it to the bench. Then slide the 1/16 x 1/4" leading edge into the leading edge notches cut in the rib noses. Lastly, glue the top spar in place. Cut the wing-tip pieces from soft 1/8" sheet and cement them in place. After the wing is removed from the form, round the front edge of the tip and shave the rear edge to a sharp-edged taper. Brace the tip with short pieces of 3/32" square to prevent warping when covered. Dihedral is accomplished by cracking the wing at the center and blocking up one tip three inches off the bench. Hold the other side flat on the bench. Cement the cracked center generously to hold position. Covering. Using thick dope for adhesive, attach the paper to one fuselage side at a time. Trim the edges neatly before going on to the adjacent side. The stabilizer and rudder are each covered with two pieces of tissue (Silkspan was used on the original model), one piece for each side of the surface being covered. The wings are covered with three pieces of paper, one for the bottom, and one for each side on the top. Attach the paper to end ribs and wing edges only. Spray the finished covering with water and allow to dry taut. Then follow up with a coat of thin clear dope. When spraying the tail surfaces and wings, pin them to the bench until dry to prevent warping. The wet paper will not adhere to the bench. Spray one half of the wing at a time. Propeller. The propeller blank is cut to the outlines on the plan from a medium-hard balsa block 1-3/4 x 1 x 8". Do not round the tips until carving is finished. Carving is, done in the usual way. Carefully balance and sand the finished prop. Use at least eight strands of 1/8" flat rubber with no slack. The nose block is shown. Glue a washer to it for a bearing and another to the rear of the prop hub. Use a loose washer on the shaft. FLYING The tail surfaces are cemented permanently in position. The wing is loose for convenience, being held in place by rubber strands run over the wing and around two wire hooks fastened one on each side to the fuselage at Station 4. Test glide the model over tall grass if possible. If properly built, the model will be tail heavy. Since the wing cannot be moved back and forth for adjustment, a slight amount of downthrust will remove any stall, but if the stall should be severe, add a little weight to the nose. Insert a sliver of wood behind the top of the block for downthrust. Remember occasionally to place a drop of oil on the propeller shaft between the bearing washers. Scanned From November 1941 |