|

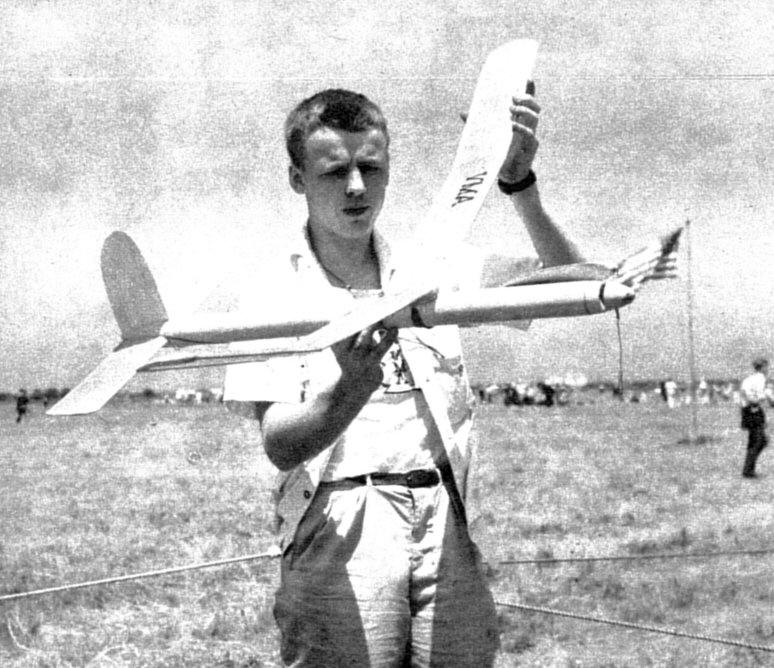

Slick Stick Even before we saw it fly we bought this beautiful stick right out of the packing case the night before the Nationals. P. S. It placed close to the top! BY CALDWELL JOHNSON

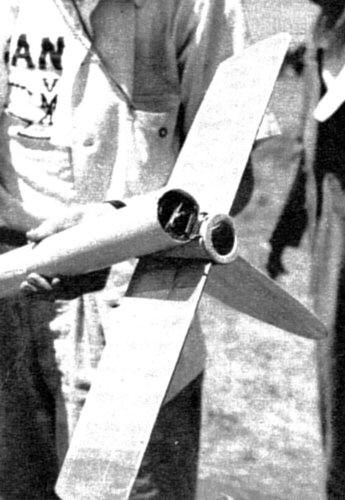

THE stick model has again definitely come into its own. This is shown by the numerous entries in both this and last year's Nationals. After being ousted for a time there was such a clamor from all parts of the country that the officials of the larger meets saw that they must once again include the old Lsq./100 square-inch jobs. In our efforts to produce a well-designed model we tried to find the optimum relation between practicability and the best design according to theory. After building and flying the model we feel that it is at least practical and consistent, and we'll leave it to you to judge its duration abilities. The wing is of rather high aspect ratio (12.5) but no trouble was experienced in either washin, washout, or folding in high winds. Twenty-eight ribs of 1/32" balsa are required. The most convenient method of cutting the ribs is as follows: After making a template of the section, cut out twenty-eight rectangles of sheet balsa that are large enough to cover the template. Cement these pieces together one above the other with dope and dope the template on top. After the dope is dry, saw the block to shape on a band or jig saw and sand. The ribs can then be split off quite easily as required. The wing is multispar construction, with eight 1/16" square spars and 1/8" square leading edge. The tips are carved from light balsa. Cover with 00 Silkspan. The horizontal tail is constructed similar to the wing. The vertical fin is 1/16" sheet balsa covered with Silkspan. Don't forget to glue well to tail fairing and cement a soft copper wire across the grain to warp the rudder if necessary. While at first glance the stick may appear rather tedious to build, it is not so. Only two pieces of 1/16" sheet balsa are used to cover the entire stick. Cut the bulkheads from1/8" sheet balsa and cut them in half. Pin down one side to the work board. Cover with a single piece of sheet balsa. After this has dried remove from board and cement the other halves of the bulkheads and cover. Reinforce the two end bulkheads with small wedge-shape pieces of balsa. The wing mount is built on the fuselage over a piece of wax paper. After drying, cement to wing. The nose plug is laminated from 1/4" sheet balsa with the forward end recessed to allow room for the tensioner. Solder a washer around a 1/16" inside diameter brass tube about one quarter from one end. Insert the long end of the tube into the nose block with the short end facing forward. The tension spring is wound from .024 steel wire around a quarter-inch drill. The spring should be about an eighth inch longer than the tube projecting from the nose block. To assemble, slip the 1/16" wire prop shaft in place. The spring is then put over the shaft and tube and followed by a washer, ballbearing thrust washer and another washer which is soldered to shaft after a right-angle bend is made in shaft. The "stop" is located after the prop is in place. Don't let the single-blade floater blade worry you -- it'll work well. Being partial to single-blade props, we searched for some method to do away with the terrific aerodynamic unbalance in the one-blade props. Letting centrifugal force hold the blade perpendicular to the axis seems to solve the balancing problem to a great extent. Besides, you'll never break a prop with this hinge. The hinge is a 1/16" inside diameter brass tube soldered to an .010" brass strip which is bent to fit prop hub and securely bound and cemented to blade. Balance with solder on 1/32" wire. Use this relatively light wire to absorb landing loads. The tail fairing is carved from a block of soft balsa which is split and hollowed. The stab is cemented in place before cementing the fairing together. The tail hook is cemented to a plywood plug which should fit snugly into rear of stick. The leading edge of the stab will have to be notched to clear winding eyelet in tail hook. The hinge for the fairing is formed from steel wire and a 1/8" rubber band is fixed to tail fairing and stick to hold tail in position. To wind motor the tail is folded downward and the tail plug pulled out. The model seemed to fly best with a tight left circle in a glide and a flat, fast climb to the right. Adjust model to glide to the left and then add right thrust until model circles to the right under power. Eighteen strands of 3/16" flat rubber in a 40" loop will do the job. This model will afford many hours of pleasant flying and we're sure will give a good account of itself in a contest. Scanned From March 1942 |

||||