|

WHY NOT PUSHERS? The author's consistent contest victories prove that

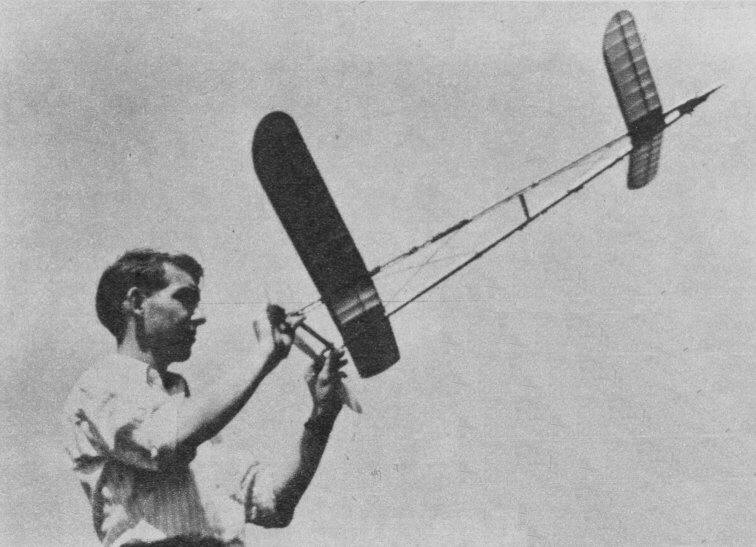

YI, he launched it backward!" "Boy, what a head wind! Oh

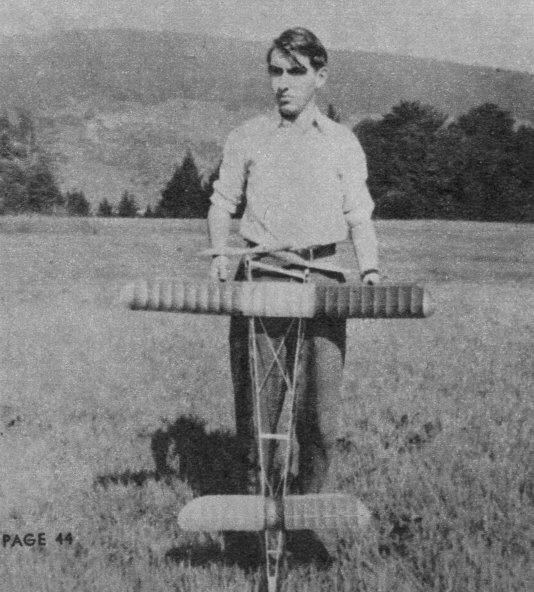

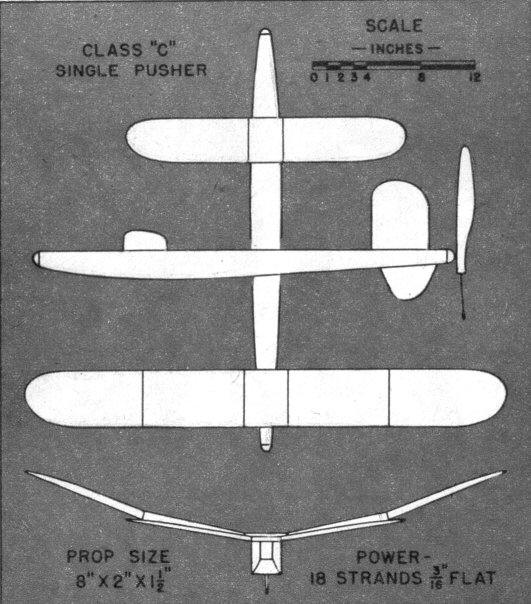

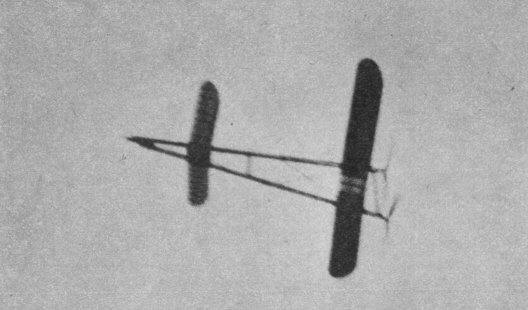

-- it's a pusher." And so it goes. Anyone who builds pushers nowadays is regarded as a die-hard, a throwback or just a plain nut. Is all this ridicule deserved, or should we give the pusher another chance? Prior to 1933 the only type of outdoor stick model seriously considered as being capable of winning contests was the twin-pusher. Tractors were unstable and too hard to adjust. Then in 1933 through the use of larger stabilizers and the discovery of the principle of the offset thrust line, a tractor won first place in the Nationals. Immediately modelers began to build tractors, arguing that here was a ship that was easier to build, was lighter, glided better, and finally, looked more like a real airplane. By 1936 the pusher had practically vanished. The author, realizing that the pusher has good qualities not found in tractors, has been experimenting with such models for the last few years. Presented here are the results of his experiments, in the hope that other builders will find them helpful and will renew the competition between the pusher and the tractor. Longitudinal Stability. Perhaps the most outstanding characteristic of the pusher is its great longitudinal stability. In a tractor we obtain longitudinal stability by using a large lifting stabilizer, the idea being that as the angle of attack of the model begins to increase, the tail lifts the rear end of the ship, keeping the nose down and preventing a stall. In the pusher we have the same set-up except that what was formerly the tail is now the main supporting surface, and can exert a much greater stabilizing force. It may be noted that having the larger surface at the rear produces another very interesting effect whenever the model is stalled by a gust of wind. A properly adjusted model, either pusher or tractor, always has its front surface stall first, thereby causing the nose to drop and the model to dive in order to regain flying speed. The forward surface of a tractor represents about 75 percent of the total lifting surface, and when this ceases to function the model drops rapidly until speed is regained. The forward surface of a pusher, on the other hand, is only 33 percent of the total lifting surface, and the loss of this part of the lift for a second or so will not greatly increase the sinking speed of the model. This explains why a poorly adjusted pusher is often seen to soar out of sight. Spiral Stability. Pushers are just as stable spirally as are tractors. The method of obtaining spiral stability is the same in either case, namely, to locate the center of lateral area a little to the rear of the center of gravity. If a newly designed pusher flies with the rear end swinging from side to side, the C.L.A. is ahead of the C.G. The cure for this is to decrease the dihedral of the elevator or increase that of the wing. A model which tends to dive spirally into the ground probably has the C.L.A. too far to the rear, although insufficient angular difference between the wing and elevator may be the cause. Since the twin-pusher has two propellers rotating in opposite directions, the torque effect is entirely eliminated. A properly aligned twin-pusher will show no spiral problems, even when fully wound. Propellers, Motors. Each propeller of a twin-pusher should have a diameter of about 70 percent of that of a single-propellered model of the same size. This gives considerably more blade area than a single-propellered model of the same size would have, resulting in a longer motor run and yet a rapid climb. Each motor should have about half as many strands as would be used in a single-propeller model of the same size. This enables a very large number of turns to be stored in each motor, and consequently the motor run is very long.The twin-pusher described in the drawing is a time-tested contest design. Out of eight contests entered, it has won four firsts, one second, one third and two fourths. The longest flight to date with this model is 11:40.2, out of sight. The wing area is 160 sq. in., and that of the elevator is fifty percent that of the wing or 80 sq. in. The required weight is 4.80 oz. Be sure to use firm balsa for the fuselage and to coat all joints several times with cement. If the fuselage is properly built the propellers will clear each other and the fuselage with room to spare. The rest of the model is of conventional construction. Flying. Fasten the wing and elevator to the fuselage with rubber loops and put two motors of ten strands of 3/16" rubber, each 40 in. long, in place, closing the propeller and S hooks with small rubber bands. Place a piece of 1/8" sq. under the leading edge of the elevator and glide the model, moving either the wing or elevator backward if it stalls, or forward if it dives. When the model glides smoothly, wind each motor about 250 turns and release the model. It should fly smoothly both in climb and glide. A smooth climb and stalling glide indicate that the angular difference between the wing and elevator is too low. Increase the incidence of the elevator. A stalling climb and smooth glide indicate too much incidence in the elevator. The model will probably fly in large circles either to the left or right. If it does not, set the elevator askew on the fuselage. The end which is farther forward will be on the outside of the circle. The model may also be made to turn by washing out the end of the wing which is to be on the inside of the circle. Continue to fly the model, gradually increasing the power until you are storing about 1,200 turns in each motor. If any "bugs" appear, straighten them out before going to higher power.Single-pusher. The design of a single-pusher presents much the same case as the twin-pusher, except that here we have torque problems. The model will glide somewhat better than the twin, but the motor run and climb are cut down to those of a tractor. The model in the drawing presents no difficulties. It flew best in left circles, both in the climb and glide. The adjusting procedure is the same as that for the twin, except that a little side thrust may be necessary in order to control the torque.Further Improvements. A twin-pusher with inclosed motors should be quite easy to construct. Folding propellers were not used on these models as they would act as rudders extending behind the model and steer it into the ground. A successful pusher folder should fold forward against the fuselage. This would necessitate some sort of a spring to pull the blade forward.Scanned From December 1941 |

|||||||||