|

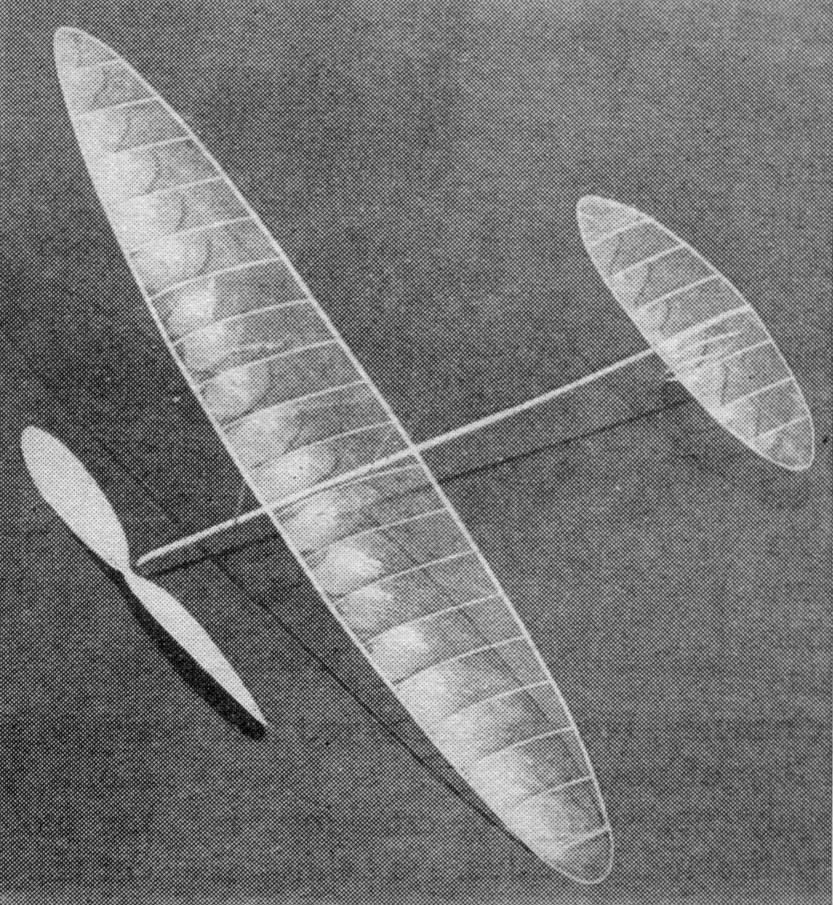

King of the Indoors There's regal dignity in the long,

leisurely flight of this big plane by Lawrence N. Smithline

THE spoiled child of models, the indoor tractor, has captivated the builder's imagination because of its seemingly majestic and apparently very deliberate flight. Every turn of the propeller has a very definite effect which you can see. Small models, particularly the R. O. G., when compared to the large tractor, seem to buzz around a while and then flutter clown. A successful model requires a great deal of care, patience, and discrimination. Every piece of material must be carefully selected for weight and strength before it can be used. However, in spite of the size of our Class C tractor (the class with wing area between 100 and 150 square inches) the cost of building one is extremely low. Sixty cents will pay for all the materials necessary, and leave some over. MAKING THE WING The shape of the wing is what is known as a swept forward or double ellipse. The center-section spars should be cut from 5 lb. 1/16" stock, made 5/32" wide at the center and tapered to 1/8" at the dihedral. Round off the edges and sand the spars smooth with #10-0 sandpaper. The center spars should weigh .0085 oz. The tip spars should he cut from 4-lb. balsa of 1/16" sheet 1/8" wide tapered to 3/64" at the tip. The tip spars, after sanding and smoothing, should weigh .008 ozs. The ribs should be cut from 1/32" sheet in the following way. Cut along the template; then move the template down 1/32" and cut again. The total weight of the 17 ribs should be .002 ozs. In inserting the ribs, the oversize ones should be trimmed to size by cutting one third the excess from the front and two thirds from the rear. Make a cardboard template of the tip, soak two 1/32 x 1/64" strips in water, and bend them around the templates. After they have dried, butt-joint them to the spars. The wing should be made and covered in one piece and the dihedral should be put in after the wing is covered. Heat-treat the wing at the dihedral to take out cover wrinkles. Make the clips of .014" diameter wire and cement them in place. Make sure they are perfectly straight when drying. MOTOR STICK AND TAIL BOOM The motor stick is bent around a former of the following dimensions: 3/8 x 5/32" at the center, tapered to 1/4 x 1/8" at the ends, 15" long. The blank should be cut from semi-quarter-grained balsa of 1/32" stock, 1-1/16" at the center tapered to 13/16" at the ends. Soak the blank in hot water, bend it around the former, and bind it with 1/2" tape. After it has dried, cement the seam, angle the front end, and put caps over the front and rear ends. Sand the motor stick smooth with #10-0 and cement the thrust bearing, the rear hook, and can in place. The motor stick should weigh .0175 oz. and should be strong enough to take 7/64" rubber. The boom is bent around a former 1/4 x 3/32" tapered to 3/32 x 3/64" and 10" long. The blank is made from quarter grained stock 1/64" thick sanded to a paper thickness, 11/16" tapered to 5/16" and 10" long. Soak the blank in hot water and proceed as with the motor stick. It is not necessary to put caps on the boom. Merely pinch the small end together and cement it with a drop of cement. The boom should weigh .0034 oz. Cement the large end of the boom to the rear end of the motor stick. Make sure that the seam is down, and that it has the proper angle. TAIL The stabilizer or elevator and rudder are of the same shape as the wing. Make a full-size drawing of them both, pin your spars down and cement the ribs in place. Make a template of the tips (bend them in the same way that you bent the wing tips) and then after they have dried, butt-joint them to the spars. Cover the tail assembly with light microfilm and attach it to the boom with several drops of cement. Make sure that the stabilizer and rudder are at right angles to each other. The tail pieces complete should weigh .0035 oz. PROPELLER The propeller has always been the average modelist's nemesis. Actually carving propellers is not so hard as it is cracked up to be. The art requires only patience, care, and the ability to follow instructions. If your impatience is likely to get the best of you, finish a semi-carved prop. Not only will it take less time, but it will be more accurate. If you use a semi-carved prop, get one of 17" diameter and a pitch-diameter ratio of 1.8. This gives you a pitch of 30.6". Cement both halves together and let it dry. If you must carve a block, use one of the following dimensions: 17 x 1-1/8 x l-15/I6". Draw the diagonals on the wide face, mark off the hub, and cut the block into a blank by trimming away the balsa to the lines. Then start carving your blank. Always carve the concave sides first and completely finish them with sandpaper varying from #2 to #10-0. Then carve the convex side. The blades, just after carving but not yet sanded, should be 5/16" thick at the hub, tapered to 1/16" at the tip. Sand the blade with rough sandpaper and then with finer and finer grades until the hub is 3/64" thick and the tip is paper thin. When sanding, support the blade only with your fingers. To support it on something else will undoubtedly warp it out of shape and may even cause you to break the blade. Make a template of the blade shape and cut your prop outline to fit it. Then finish the edges again with rather fine sandpaper, finally ending up with #10-0. Make a shaft of .016" diameter wire, insert it into the hub and cement it into place. Put on two flat washers; one should be cemented to the back of the hub and the other should be free. The semicarved prop is finished in exactly the same way, saving you all the heavy carving. If you wish, and are expert enough, you may make a microfilm prop. (See AIR TRAILS, December, 1936.) If you do, use a 17" diameter and 1.8 p.-d. ratio in the microfilm prop also. Wooden propellers of this diameter should weigh about .018, microfilm props about .008 oz. ASSEMBLY AND FLYING Clip the wing on to the stick so that the can is just about halfway between the leading and trailing edge. Bind the clips with a bit of silk thread in order to prevent the clips from sliding around on the motor stick. Hook on the propeller and slip a 20" loop of brown 7/64" rubber on the shaft and the rear hook. Wind the rubber about 200 turns and release the model. If the ship stalls, move the wing backward; if it dives, move it forward. Wind up the rubber more fully, about 1,000 turns, and release. If there is a slight tendency to stall, wash out the left tip of the tail. Another anti-stall device is to put a negative incidence in the prop. Both these dodges are not good if the stall is a real one, when the only remedy is to move the wing back. Fully wound to about 2,500 turns, the model should fly, under good conditions and with a reasonable amount of luck, 27 to 28 minutes. The original model, with 2,000 turns, flew 22 minutes, of which 350 turns were not used. Flights of 14 minutes have been turned in by the model beneath a 35-foot ceiling. This should encourage those builders who do not have the advantages of a high ceiling.

Scanned From January 1937 |

||||||||||||||||||||||||||||||||||||||||||||