|

The

original model was burned by smoke screen apparatus before finished photos

were made, but it proved to be a fine flier |

|

|

The

original model was burned by smoke screen apparatus before finished photos

were made, but it proved to be a fine flier |

|

THE GREAT SOPWITH

‘CAMEL’

by JOSEPH H. WHERRY

EVERY now

and then in all lines of endeavor a truly great event takes place. This is true

in aviation as well as in other industries. The event which the author has in

mind took place in late 1917 - it was the appearance in squadron strength of

the famous Sopwith Camel scout fighters

over the Western Front.

No sooner

had the Camel received its baptism of

fire than such aces as Collishaw, Little, Frew, MacLaren and others too

numerous to mention began to roll up impressive numbers of victories at the

expense of Kaiser Wilhelm's Imperial German Air Force. Even the great Baron

Manfried von Richthofen had the somewhat disaster-filled distinction of being

shot down over the Australian sector of the British lines by a young Canadian

airman, Capt. A. Roy Brown, who finished the war with 13 Jerries to his

confirmed credit. Yes, Brown polished off the great Red Knight who had about 82

Allied aerial scalps credited to himself. Richthofen, at the time of his death

early in 1918, was flying a Fokker Triplane D.R.1.

Here are,

just a few of the Camel's points of

interest: span 28 ft.; length 13 ft. 9 in.; speed about 115 mph, and cruising

time 2-1/2 hours. It could climb to 5,000 ft. in 5 minutes,

and below 12,500 ft, it was the most maneuverable ship on any front any time

during the war. All of this remarkable performance was accomplished with a 130

hp Clerget Rotary. Later in the war Camels

were reaching the front equipped with 150 hp Bentley, and finally 230 hp

Bentley motors. Camels even served

the British Royal Navy as shipboard fighters. The decks of the old carrier

Furious of the Royal Navy echoed to the battle rhythm of the historic Camels.

Statistics

show that squadrons of the Royal Flying Corps destroyed at least 905 enemy

aircraft, while the Camel units of the

Royal Naval Air Service destroyed over 370 along with one zeppelin and several

kite balloons. This gives a grand total of at least 1275 enemy aircraft as

having fallen to the tune of guns manned by the young British pilots. This does

not count the many victims of Camels

flown by the Yanks, Belgians and even French; yes, even the latter purchased

some Camels for their

"Chasse" escadrilles. With their two twin Vickers guns (sometimes

one Vickers was mounted, supplemented by a Lewis gun over the center section

which was uncovered for better visibility), the Camel pilots proceeded to whip many times their number of Jerries.

During the

1920's the Sopwith firm underwent a change in organization and emerged as the

now famous Hawker Aircraft Co. The established and proven aeronautical design

principles remained, however, and the modern Hawker Hurricane, Typhoon, and

Tempest fighters of current fame are the direct descendants of the Sopwith Camel, Snipe, Ddlphin, etc.

With this

background in mind, you can readily see that no modeler's tarmac is complete

without one of the greatest fighter planes that ever worried the "Master

Race." If the accompanying plans and instructions are followed, you will

be rewarded with a model that will be a beauty to behold, and one that will be

a thrill to fly.

One word of

caution: the author strongly recommends that no accessories such as

smoke-screen apparatus be installed. The writer, when he built the model

pictured here, was interested in various gadgets. If he had not been in such a

hurry to try out such miniature luxuries he might still have had his model Camel; at least he would have had a

complete set of photographs to remember it by. That smoke-screen gadget, which

was actually successful to a certain extent, caused the model to burst into

flames after one particularly beautiful takeoff. All the friendly Gremlins on

the model flying field could do nothing and the model was destroyed even before

the decorative checkerboard design was applied to the entire tailplane. Just

build a good model, fly it in an orthodox manner, and you will avoid learning a

lesson the hard way as the author did to his disgust.

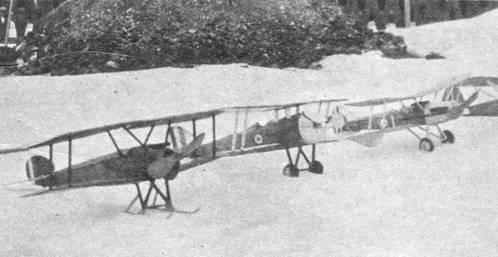

The model

shown wore skiis throughout its short career and it performed spectacularly on

snow and ice. Wheels can be easily fitted; however, if you have never had the

experience of flying a model with ski gear here is one that will provide many

thrills.

FUSELAGE - We begin by building the two

sides of 3/32" square medium grade balsa. Note that this basic framework

is shown on side and top views by the solid black construction. The two sides

are joined together, first at the tail post, then working forward. Crossbraces

of the same 3/32" square balsa are placed in like positions at top and

bottom of fuselage. While this structure is drying, cut the side formers (two

of each) from 1/32" sheet balsa and cement in their proper places. Cut

formers 1, 2 and 3 from 1/16" sheet balsa and cement in place on top of

the fuselage frame. Now, from 1/32" sheet balsa, cut formers 4, 5, 6 and

7; install in their proper places. All stringers on fuselage sides are of

1/16" x 1/8" hard balsa; stringers on fuselage top aft of the cockpit

are 1/32" x 1/16" hard balsa; and the two short stringers which join

formers 1 and 2 forward of cockpit are 3/32" square balsa. When all

stringers are installed, sand the entire framework to make it as smooth as

possible.

The author

suggests that a strong grade of bond paper be employed to cover the space

between 1 and 2 top formers as well as to form the cockpit. Using small pieces

of 3/32" flat soft balsa, fill in the space on each side of fuselage where

the wings connect with the fuselage at the lower longeron. This filling in has

been noted on the plans as the Wing Support Gusset. With razor blade and

sandpaper, work this support gusset down to where it blends in with the side

formers and lower longerons. You will find that this makes a very rigid

assembly to which the lower wings and the landing gear struts may be easily

joined. Insert the rear motor hook of .004 music wire. From soft balsa carve

the solid balsa block which fills the space between No. 1 former and the

cowling on fuselage top; sand to a smooth shape, cement in place, and sand

further so as to cause it to blend in with fuselage.

The

fuselage framework is now complete; we need only the cowling to complete this

unit. The cowl is formed of seven layers 1/8" medium grade sheet balsa.

With a compass, mark the correct size circles and cut out with razor blade or

scroll saw. (The radii can be easily determined from the cross sections shown

in side view on Plate la.) Note that the third layer from the front is solid

except for the small 1/4" diameter hole at center; note also the two

smaller circular layers which form a base for the nose plug. When all cowl

circles have been shaped, cement together by laminating and allow considerable

drying time. When dry, carve and sand to the correct profile. Note that the

cowl is irregular in shape on the bottom when viewed from the side. This

irregularity allowed for the escape of the hot castor oil laden exhaust fumes

of the Camel's rotary motor. The

author chose to lighten his model by not including a detailed motor inside the

cowl; this motor, if like that on the original ship, should revolve. However,

if some of you wish to include a detailed motor, you should have no trouble

finding details in old issues of this magazine. The cowling is cemented flush

to the front of the framework; and with this operation finished our Camel fuselage is complete.

EMPENAGE - Both rudder and elevators are

easily built directly over the plans on Plate 1b. In the interest of lightness,

because this quality is most essential in flying scale models, the author

recommends that tail surfaces be constructed of 1/16" flat medium weight

balsa. Widths of the various members may be taken from the plans. The tail surfaces

of First World War aircraft were generally speaking flat, the only deviation

being the very thin trailing edge as shown in the cross section of the

elevators. A thorough sanding with very fine sandpaper will do much to further

a successful covering job.

WINGS - The only difference between

upper and lower wing panels is shown on Plate 2 by means of dotted lines. To

make a set of plans for the left wings, merely trace the right wing panel and invert

your tracing. The wings are best constructed of medium grade balsa; directly

over the plans, the dimensions are noted on the plans with the exception of the

tips which are made from 1/16" flat scraps. The author recommends straight

grained pine be used for the wing spars; this adds strength to the very thin

wing section. Note that two small center section strut supports are installed

in the top wing panels flush with the bottom surface of wing. Be certain that

you install the two small gussets at the root ribs of each panel.

The center

section is also constructed directly over the plans. The ribs are cut from

1/16" sheet balsa as are the main ribs; three are needed. When all wing

panels have been constructed, carve leading and trailing edges to the proper

cross sections shown on the rib pattern. Some builders may prefer to shape

these parts before they have been cemented to the wing structure; however the

author prefers to shape them, after assembly, with a razor blade. When all

panels are complete, sand entire structure with fine sandpaper. Most dime stores

sell a number of small "emery boards" of the type used by women on

their finger nails; you will find these of great use in sanding the completed

frames and in preparing them for a smooth covering.

STRUTS - The patterns for the landing

gear struts, landing gear spreader bar, and the center section struts are found

on Plate 2. The interplane struts can be measured directly from the side view

on Plate 1 (since interplane struts are installed vertically, there is no

distortion). All struts are cut from 1/8" x 5/16" hard balsa and are

streamlined, sanded and clear doped. The spreader bar is made from medium balsa

and is 3/16" thick and 11/16" wide. The two 1/8" square pine

axle supports are cemented firmly in notches. Streamline the spreader bar as

shown and sand well, then follow with a good coat of clear dope.

Realism can

now be added to these struts by color, doping them with a brown dope. This will

resemble the struts of early combat planes. Likewise, doping the struts before

assembling will aid in securing a neat model; doping struts in the vicinity of

a good covering job is not conducive to neatness.

COVERING and DOPING - Because most First War Camels were of rather dull coloring, the

author suggests a khaki or olive drab colored tissue be used. This will give a

desirable color, and at the same time will tend to hold down the weight of the

finished model. Covering should always be done with the grain of the tissue

running the long way of the part being covered. Because of the concave shape

of the undersurface of the wings the tissue adhesive should be applied to each

rib. One piece of tissue can be used for each side of each wing panel with the

exception of the tips which should be covered with a small separate piece. The

fuselage is covered with a series of small pieces, and the tail surfaces can

easily be covered with one piece to each side. Be certain the covering is

neatly cemented around leading and trailing edges, etc., so as to leave no

part exposed.

Because of

the light construction of the tail surfaces, merely spray lightly with water and

watch for signs of warpage. The wings are also sprayed with water, as is the

fuselage, and when dry may be clear doped with a very thin coat. Insignias are

best applied before assembling, and may either be painted on by hand or they

may be of the popular decal type. Note that the British insignia follows a

slightly different pattern from that employed today by the R.A.F.; all

circular insignia is exactly the same, top, side and bottom. The rudder is decorated

with vertical stripes also of red, white and blue, with blue next to the rudder

post. Note that the center section is not covered.

ASSEMBLY - First cement the elevators in

place on top of the top longeron at rear of fuselage just behind former 7. The

rudder is cemented in place flush with the rear vertical fuselage members and

directly on top of the elevators. Take care that the tail surfaces are

properly aligned and that neither positive nor negative incidence is present

in the elevator. By the same token the rudder should exactly parallel the

center line of fuselage, bending neither to left nor right.

Now

assemble the top wing by cementing the center section in place between the two

main panels. Note that no ,dihedral is present in the top wing.

While the

top wing sections are drying firmly, cement the lower wings in place against

the wing support gusset. Note by checking the half-size front view on Plate 2

that the lower wings have 3/4" dihedral at each tip. This can be accomplished

easily by blocking in place with small boxes or dope bottles.

Install

center section struts in their proper place directly on top of the top

longerons. It will probably be necessary at this point to cut small notches in

the bond paper and balsa fill to accommodate the struts. Once installed, using

plenty of cement, and at the proper angle (check angle of installation by

holding the top wing assembly in place), these struts will form a firm support.

When center

section struts have dried securely, cement top wing in place. Note that all

strut positions have been indicated on Plate 2 wing plans with small circles.

The interplane struts are next installed. It will be advisable to cut away a

very tiny portion of covering at the point where all struts join the wings; a

much sturdier joint can be accomplished when cementing to the bare balsa.

The landing

gear is now cemented in position. When each strut is securely in place insert

the spreader bar and cement firmly. It will be necessary to slightly force the

struts apart to permit entry of spreader bar. Since all struts are colored the

wheels can be installed. The author recommends that the axles be 1-1/4"

lengths of .004 music wire. Force cement into the drilled holes in the

1/8" square pine axle supports and cement the music wire in place. Wheels

may be purchased or they may be built of laminations of 1/8" sheet balsa.

In any event they should be equipped with a small washer on each side. Wheels

are installed on the axles which are bent upward on the end. The author

recommends the bent-up axle; should you desire to make use of the ski gear the

wheels are readily exchanged by merely unbending the axle and slipping on the

skiis. The tail skid is made of pine, glued in place.

With the

addition of a nose plug and a propeller carved from the illustrated blank shown

half-size on Plate la, we find that our Camel

is indeed nearing completion.

DETAILS and FINISHING - Such details

as machine guns and gun sight are made of balsa, doped a dull black and

cemented in place. The wind screen is cut from sheet celluloid. The bracing

wires are realistic and can be added by threading a needle with a good quality

light gray thread and sewing in place. If you desire the wires to be visible in

photographs it will be best to use black thread. Indicate control surfaces by

thin strips of black tissue or by india ink. Note also the small control horns

on the wings; these can be added with scrap balsa and cemented in place on the

same rib as are the interplane struts. Note that ailerons are present on both

top and bottom wings, and that they are connected with (and actuated in part

by) a brace wire. Do not overlook the brace wires on the tail surfaces. All

brace wires are clearly indicated on the plans by dot-dash lines.

With these

details added, all that remains is to color dope the cowl after making certain

it is smooth as silk. The author used red dope on his Camel's cowl but any bright color will be attractive. The wheel

centers should be color doped also, and the tires doped a dull black.

Now your

model is finished; should you desire, when the snows come, to have a bit of

rare sport just construct the skiis shown half-size in the box on Plate la.

Bamboo strips are used for the skiis; the bamboo should be about 1/32"

thick and 1/2" wide. A small candle is utilized for making the bend in the

skiis. Bamboo held near the flame bends easily. Balsa wood is used to form the

streamline base, and a small hole with bushings should be in the base. The tiny

hooks on both the skiis and the landing gear struts are made of a small gauge

music wire for the purpose of holding rubberbands which function as shock

cords for the ski gear. Try this system and you'll be delighted with the

results. Believe it or not, Camels

were used on the Eastern Front both before and after Russia bowed out of the

first war, so it is safe to assume that Camels

did see some use on skiis.

Your model,

if built according to plans, should balance with very little additional weight

in either nose or tail. Three or four loops of 1/8" flat rubber (well

lubricated with a mixture of glycerine and green soap) should be sufficient to

give excellent R.O.G. flights.

Above all,

work with care, and follow your plans. If you do you'll have an authentic scale

model of one of the most famous planes ever to carry the insignia of the R.A.F.

The author hopes to present plans and data for the Fokker Triplane, one of the

Camel's most famous opponents, in the near future.