THE geographic

location of England makes it most vulnerable to attacks from the air, and as a

means of defense the interceptor ‑ fighter planes have been developed. These

venomous single - seaters operate at close range and it is their military duty

to sweep raiding aircraft from the sky. Such planes as the famous Hawker

"Hurricane" and the "Spitfire" are designed to rocket skyward at an astonishing

rate, be fleet enough to overtake the swiftest invader, possess a great degree

of maneuverability and finally be deadly enough to promptly dispose of the

luckless victim.

The Vickers

Supermarine "Spitfire" is not a new design; the first of this type being tested

in 1936. Production difficulties plagued volume construction, however, and it

was only recently that complete squadrons of "Spitfires" were in service. Of all

- metal construction, this aerial terror is not only one of the world's best

performers but it is also one of the most attractive. A liquid cooled Rolls

Royce engine of 1030 horsepower pulls it along at a maximum speed of 367 miles

per hour - its diving velocity exceeds even that of the famous Curtiss 75‑A for

it is said that a "Spitfire" attained a speed of nearly 700 miles per hour in a

similar plunge. Eight Browning machine guns jut from the wing's leading edge

making it one of the heaviest armed single - seaters. Squadrons of these fiery

fighters are constantly in readiness to intercept Nazi trespassers.

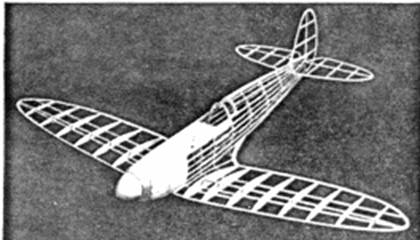

The model retains

the attractive appearance and streamlines of the original and an effort has been

made to simplify the manner of construction as much as possible while still

retaining the desired features.

The satisfaction

it is sure to afford, whether on display or in flight, will more than compensate

for the time and effort expended on its construction. After becoming familiar

with the plans and the procedure of construction, you may start to build the

Fuselage

The fuselage is constructed about a top and

bottom keel. To obtain the shape of the keel pieces it will be necessary to

trace the top and bottom outlines of the side view. A depth of 3/16" will be

about right and the keels should be cut from 1/16" sheet balsa. The bulkheads

are cut from 1/16" sheet also; two of each type are needed. Cut only the notches

shown; the purpose of this is to aid in properly aligning the stringers. Enough

of the bulkheads have notches cut in them to insure proper spacing of the

stringers and it will be a simple matter to cut the remaining ones as needed.

Pin the keel pieces into position over the side view and cement half of the

bulkheads to place. Remove from the plan and add the remaining formers. Next the

1/16" square middle stringers are added to each side. Exercise caution to avoid

pulling the fuselage out of line. Once a stringer is secured to one side of the

structure always attach one to the corresponding position of the other side.

Check continually to assure a properly aligned structure.

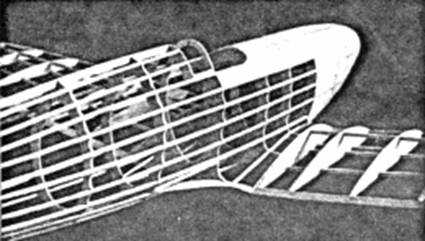

The nose of the

original model was "filled-in" with 1/16" soft sheet balsa. This is not a

difficult job but it does require time and patience. Cut individual pieces of

balsa so they will fit snugly into each open space between the stringers and

bulkheads. When dry the whole nose is thoroughly sandpapered to a smooth,

pleasing shape. Cut the nose block from a 1/2" thick block and cement it to

place. It is advisable to lightly cement the 1/8" nose plug fast, too, so the

entire nose can be shaped attractively.

Cement a "w-I"

rib to each side of the wing root, being careful to make the angle of incidence

identical to that of the plans. The trailing edge of the wing root, cut from

1/16 sheet, is trimmed to the correct size and glued to place. Brace the root

bulkheads with pieces of 1/16" x 1/8" hard balsa as indicated by the dotted

lines on the bulkhead patterns. 3/32" square pieces are fitted between the root

rib and the fuselage to form the leading edge. A 1/8" thick false rib is fitted

against the fuselage by the "cut and try" method - it extends from the leading

edge to bulkhead number b-3. Several lengths of thin bamboo may be attached to

the bulkheads to help round out the wing root.

Prepare the

fuselage for covering by thoroughly sanding the whole structure. For the best

covering job only those members of the fuselage which run from nose to tail

should touch the paper, so use a piece of sandpaper wrapped about a pencil or

similar round object to scallop the bulkheads.

Wing

Since the wing is

elliptical in plan form, all of the ribs in each half are different. Select a

sheet of soft grade balsa for all of the ribs except "w-l" and "w-2" which

require a stronger variety. Cut the required number of ribs and sandpaper them

smooth. Notches must be cut with accuracy to insure a neat job when completed.

The wing's trailing edge is cut from 3/32" sheet; the tips likewise. Select hard

3/32" square spars since they must resist the shock of landings. Assemble the

parts directly over the plans and cement the joints firmly. When dry, the halves

are removed from their jigs, trimmed and sandpapered to their final shape.

Tail Surfaces

The Spitfire's

tail surfaces haven't sufficient area to insure stable model flights so we have

enlarged them to more suitable proportions. Build the stabilizer in one piece

for greater strength. Outlines of the stabilizer and rudder are cut from 1/16"

sheet; ribs are 1/16" square. Additional strips are cemented to both sides of

the ribs and when dry they are cut to a streamline shape.

Propeller

In all

probability your Spitfire will need some extra

weight in the nose to help balance

the long tail moment arm, so we advise the use of a white pine propeller. A

hardwood prop, while a bit more difficult to carve, will take more abuse. Lay

out the blank, as indicated, on a block 9" x 1 1/2' x 1". Cut the blank to shape

with a jig saw, etc. and then carve a right hand propeller. Finish the back face

of the blades first and then reduce the front face to the proper thickness.

Shape the blades so they resemble the wood props used on early Spitfires.

(Latest models of this fighter are equipped with three blade constant speed

metal propellers.) The huge spinner will easily hide a freewheel device which

should be used to improve the model's glide. Make the spinner from hard balsa

and fit it neatly to the prop hub. The application of several coats of clear

dope with light sanding between each will prepare the prop for a smooth finish.

Remove the nose

plug and cement a block 1/4" x 5/8" x 5/8" to the back so it will fit neatly

into the hole in the nose. Drill a hole through the plug and cement washers to

both sides so the prop shaft will revolve smoothly. Bend the propeller shaft

from .040 wire; several washers will be needed between the prop and nose plug.

Covering

Cover the whole model with

colored tissue to help keep the weight at a minimum. The model pictured is all

red but the planes at war are camouflaged with dull green and brown paint. Cover

the fuselage first, using banana oil to fasten the tissue. Numerous small pieces

must be used to prevent wrinkles. Trim the surplus paper with a sharp razor

blade and then carefully overlap the next piece. It is not necessary to attach

the paper to all of frame just apply adhesive to the outsides of the area

being covered. Cover the top of the wing with several pieces, if necessary, to

avoid wrinkles. The undersurface of the wing is covered from the third rib to

the tip, only, since the landing gear must be attached to the spars once the

model is assembled. Spray a fine mist of water on the covered parts to tighten

the tissue; pin the wings and tail surfaces to a flat surface to keep them from

warping. Do not dope the covering until the parts are assembled.

Block the

fuselage into a level position so the model can be assembled accurately. Attach

the wings first; do not spare the cement for the wings are subject to the force

of landings. Check to ascertain that the incidence of each wing panel is the

same. The tips should be raised 2-1/8" for the correct dihedral. To attach the

stabilizer it will be necessary to cut the tailpost and bulkhead number 10 in

order that they can be sprung apart far enough to admit the stab. Cement the

rudder on and check for correct alignment. The landing gear struts should be

bent to shape and attached; the plan shows how the .040 music wire is formed so

as to join the spars and second rib of each wing. Draw a front and side layout

to aid in bending the wire accurately and be sure to make a right and left

strut. Use strong silk thread and neatly bind the struts to the spars. Once the

alignment is satisfactory, apply several coats of cement over all the buildings

as well as the adjacent spars and ribs. The remaining uncovered parts should now

be covered.

Complete the

construction by adding the various details. The cockpit enclosure is thin

celluloid; paper patterns should be shaped correctly before the celluloid pieces

are cut. Rubber tubing of the correct size makes excellent covers for the

landing struts, but if it is not available, bond paper should be wrapped into

tubes of the correct size. One or two coats of clear dope are brushed on the

covering; do this in a dry room to avoid "blushing." Check continually to

prevent warping of the flying surfaces. Thin strips of black tissue should be

doped to the covering to represent the control surfaces. The insignia used on

the original model was made from colored tissue, too. Exhausts, tail wheel,

wheel well covers, a radio antenna and numerous other details should be added to

enhance the appearance of your miniature.

Flying

Ten or twelve

strands of 1/8" brown rubber should be used to power this model. To many this

amount of power may seem excessive, but the resulting zip and climb makes the

model just that much more realistic. Lubricate the rubber and then remove the

excess so the sides of the body will not be splashed. Attach one end of the

motor to the prop shaft and with the aid of a weighted string drop the other end

through the fuselage. A 1/16" round bamboo pin holds the motor in the rear. Your

replica of this famous fighter is now ready for its test hop.

Select a grass -

covered field and a calm day for the test flights. Balance the model by the wing

tips it should rest with the nose pointing down at a shallow angle. If any

weight must be added, it will probably be needed in the nose. Try a few shoulder

height glides; it may be necessary to shift the center of gravity a bit to

obtain the desired results. Wind the rubber motor about 50 turns and launch. It

should climb a few feet and then glide smoothly to earth. Warp the stabilizer,

if necessary, to correct any undesirable attitudes. Should the model bank

excessively, "wash-in” the wing tip which is on the inside of the turn.

Gradually increase the number of turns once the adjustments seem satisfactory.

Stretch the rubber and use a mechanical winder for best flights. Exercise your

best judgment in the construction and flying of your Spitfire and you will be

rewarded with an attractive, fine performing model.